Efficient operation and safety are critical in HVAC and electrical systems, where precision and reliability matter most. Circuit breakers and globe valve actuators play a pivotal role in ensuring these systems function seamlessly. While Circuit Breakers protect electrical circuits from overloads and faults, globe valve actuators regulate fluid flow in HVAC systems with remarkable accuracy.

These components not only enhance performance but also contribute to energy efficiency and system longevity. Understanding their roles and integration within these systems is essential for optimizing functionality and minimizing risks. Whether in residential, commercial, or industrial settings, their impact can’t be overlooked.

Circuit Breakers: Preventing Overloads in Electrical Systems

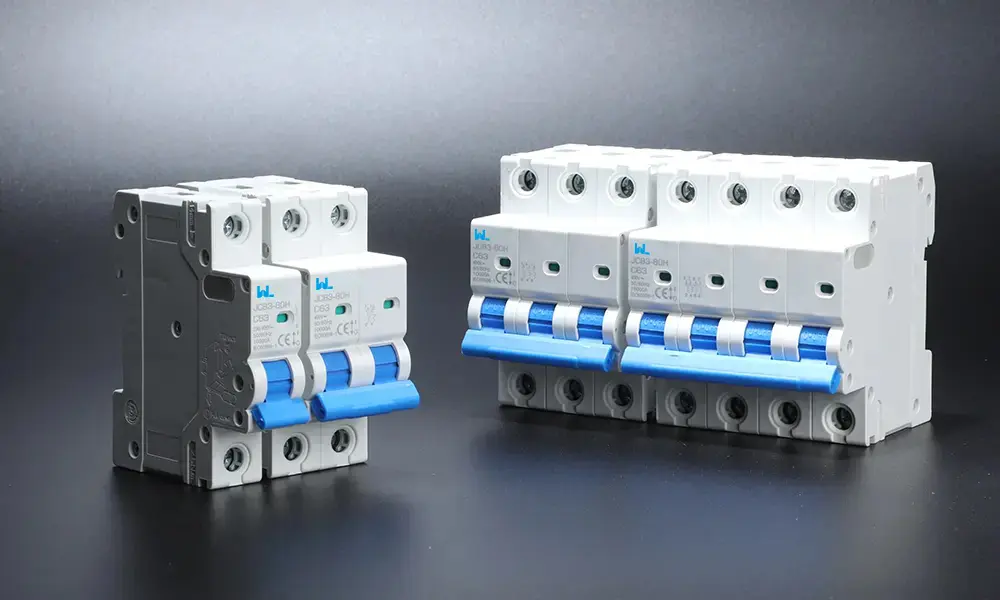

Circuit breakers interrupt electrical flow to protect systems from damage caused by overloads or short circuits. They detect irregular current levels and disconnect the circuit instantly, preventing equipment failure, fire hazards, and costly downtime. By isolating faulty sections, circuit breakers ensure the rest of the system operates safely.

Modern electrical systems frequently use circuit breakers due to their reliability and efficiency. These devices replace traditional fuses in many settings because they’re reusable after a fault is corrected. With advanced designs, circuit breakers can handle high voltage and current capacities, making them suitable for residential, commercial, and industrial applications.

Integrating circuit breakers into electrical systems simplifies maintenance and enhances safety. Smart circuit breakers, equipped with monitoring capabilities, provide real-time data on electrical loads, helping predict and prevent potential issues. They contribute significantly to energy management and system optimization in large-scale facilities.

How Globe Valve Actuators Automate HVAC System Operations

Globe valve actuators automate the adjustment of valves in HVAC systems to regulate fluid flow with precision. They respond to system inputs from thermostats or control systems, ensuring accurate modulation of heating, cooling, or ventilation processes based on demand.

Automation reduces manual intervention, increasing system efficiency and reliability. By maintaining consistent flow rates, globe valve actuators optimize thermal exchange in HVAC components like boilers, chillers, and air handling units.

Modern actuators integrate with building management systems (BMS), enabling remote monitoring and control. Advanced designs feature variable torque settings and position feedback for enhanced performance. This integration facilitates energy efficiency by adjusting valve positions according to fluctuating load requirements.

Reliable Globe Valve actuators also extend system lifespan. They prevent valve wear caused by abrupt or excessive adjustments, ensuring smooth and durable operation over time. In commercial and industrial HVAC applications, their precision contributes significantly to maintaining operational stability and reducing energy consumption.

Key Advantages of Using Circuit Breakers in Modern Systems

- Enhanced System Protection

Circuit breakers safeguard electrical systems by identifying and interrupting overloads or short circuits. They prevent damage to electrical equipment, reduce fire hazards, and ensure operational continuity in both residential and industrial setups. - Reusability and Cost Efficiency

Unlike traditional fuses, circuit breakers reset after a fault is corrected, eliminating replacement costs. This feature makes them cost-efficient for long-term use and ensures minimal downtime in critical systems. - High Voltage and Current Handling

Advanced circuit breakers manage a wide range of voltage and current capacities. They’re ideal for applications in modern infrastructures, including high-demand industrial facilities and commercial buildings. - Smart Monitoring Capabilities

Smart circuit breakers equipped with monitoring technology provide real-time data on load conditions and fault events. These insights optimize energy usage, streamline maintenance efforts, and enhance system diagnostics. - Compatibility with Various Systems

Circuit breakers integrate seamlessly with electrical grids and control systems across HVAC applications, offering reliability in diversified operational environments. Their adaptability supports growing system demands in energy-intensive industries.

Optimizing Fluid Control with Globe Valve Actuator Technology

Globe valve actuators enhance precision in regulating fluid flow within HVAC systems. They automate the opening and closing of control valves, enabling efficient modulation of heating, cooling, and ventilation processes. By receiving input signals from thermostats or building management systems (BMS), they ensure continuous adjustments aligned with real-time load demands.

Integration with BMS allows for remote operation and monitoring of globe valve actuators. Features like variable torque settings and position feedback enable precise control, reducing energy wastage and lowering operational costs. This seamless coordination ensures optimal performance of HVAC components such as chillers, boilers, and heat exchangers.

Modern globe valve actuators contribute to extended system lifespan by preventing valve damage from abrupt force or inaccurate positioning. Consistent control of flow rates minimizes wear while supporting steady thermal exchange. Their reliability plays a critical role in stabilizing HVAC operations across residential, commercial, and industrial applications.

Comparison Between Circuit Breakers and Fuses for Safety

Circuit breakers and fuses both protect electrical systems from overloads, but they differ in functionality, reusability, and efficiency. Circuit breakers interrupt electrical flow using an electromechanical mechanism that trips during faults. Fuses, in contrast, melt their internal element when exposed to high currents, creating a break in the circuit.

Circuit breakers offer reusability, as they can be reset after a fault is resolved. Fuses, however, require replacement with new units. This makes circuit breakers more cost-efficient in systems experiencing frequent electrical faults. Modern circuit breakers also handle higher voltage and current capacities, ensuring compatibility with industrial and commercial applications. Smart circuit breakers integrate advanced monitoring features, enabling real-time fault detection and load analysis to enhance safety and energy management.

Fuses respond more quickly to overcurrents than traditional circuit breakers. However, the need for manual replacement and their incompatibility with modern energy-management systems limit their effectiveness in advanced electrical networks. Circuit breakers are considered a reliable and scalable choice for systems demanding high performance and frequent safety interventions, such as those incorporating Globe Valve Actuators for HVAC automation.

Enhancing Building Automation with Globe Valve Solutions

Globe valve actuators play a critical role in streamlining building automation by enabling precise control over HVAC systems. These actuators regulate the flow of fluids like water, steam, or chilled water with high accuracy, ensuring stable performance across heating, ventilation, and cooling processes. Their automated operation reduces human intervention and minimizes errors in valve adjustments.

By integrating with building management systems (BMS), globe valve actuators provide centralized control and monitoring capabilities. This integration enables dynamic flow adjustments based on real-time system requirements, improving energy efficiency. For instance, adjusting valve positions in response to changes in load demand can optimize chiller and boiler operations, resulting in significant energy savings.

Modern globe valve actuators feature advanced mechanisms, such as variable torque settings and position feedback, that enhance their adaptability to diverse HVAC applications. These features improve system reliability by preventing valve damages caused by abrupt pressure changes while maintaining consistent flow rates. When used alongside circuit breakers in automated systems, their precision contributes to enhanced safety and operational stability.

In high-demand commercial or industrial properties, globe valve actuators ensure thermal exchange efficiency by maintaining optimal fluid flow. This capability extends the lifespan of HVAC components, reducing maintenance costs and downtime. As these solutions continue evolving, their role in refining building automation and energy management becomes increasingly indispensable.

The Impact of Circuit Breaker Innovations on Energy Efficiency

Circuit breakers and globe valve actuators play pivotal roles in advancing the safety, efficiency, and reliability of modern HVAC and electrical systems. Their ability to integrate with smart technologies and adapt to diverse operational demands ensures they remain indispensable in both residential and industrial applications.

By combining precise automation, real-time monitoring, and enhanced system protection, these components contribute to streamlined operations and reduced energy consumption. As technology continues to evolve, their importance in optimizing performance and supporting sustainable energy practices will only grow, solidifying their place in future system designs.